10

2025

-

10

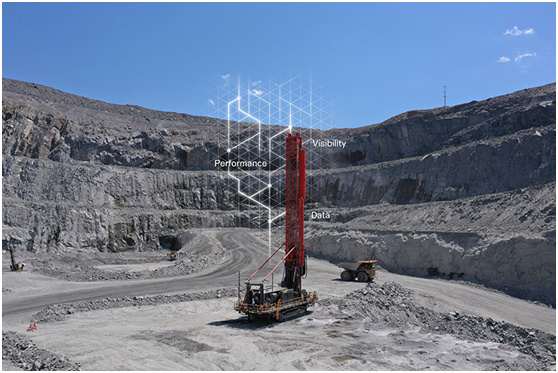

Sandvik’s remote monitoring service technology expands to open-pit surface equipment

The world’s biggest miners have been deploying Sandvik’s Remote Monitoring Service (RMS) for fleets of trucks, loaders and drills at underground operations around the world for years.

The world’s biggest miners have been deploying Sandvik’s Remote Monitoring Service (RMS) for fleets of trucks, loaders and drills at underground operations around the world for years.

RMS is a predictive maintenance service Sandvik provides that remotely monitors and analyzes telemetry data from equipment fleets. RMS can effectively identify abnormalities, determine root causes and provide actionable information to eliminate defects.

All this ultimately increases equipment uptime and utilization.

Until now, the services only existed on underground mining equipment, but the global engineering group is rolling out RMS to its surface equipment, including rotary and boom surface drills.

Esa Matilla, Sandvik’s Digital Services Portfolio Manager says the company continues to unlock the value of data by expanding RMS to surface mining.

“Remote Monitoring Service strengthens the partnership between us and our customers. We work collaboratively to drive continuous improvements and maximize the potential of the Sandvik fleet,” Matilla says.

R&D leads to rapid growth

Chris Ewing, Sandvik’s Digital Services Manager, US, notes that while Sandvik’s history is rooted in underground mining, much of the technology has migrated to other areas, namely to surface drilling.

“Now we have capabilities to do open pit and surface mining,” Ewing says. “We've had a lot of rapid growth and adoption, particularly in the US. The focus has now shifted to expand those service offerings on the surface machines.”

Ewing adds that through the research and development (R&D) process, the US team has seen quick growth and adoption by the market.

Combined with a global pool of reference data and Sandvik’s in-depth analytic skills, RMS can help miners achieve increased productivity with lower emissions, while extending equipment and component life.

Previous article

Previous article

RELATED INFORMATION

2024-02-10